Fuelsampler

Fuelsampler Aps had a product with potential and partnered with Sinoscan to scale up production

Are you considering outsourcing part – or all – of your production? Read on and see how implementing a scalable production program helped Fuelsampler ApS to prepare for their growing market.

Background

The Danish OEM company Fuelsampler ApS, develops and manufactures fuel samplers for the shipping industry. Leveraging the owners’ technical expertise and experience with marine diesel engine repair and maintenance at their sister company, Marco Marine, Fuelsampler has for 20 years developed and manufactured automated pneumatic fuel samplers that increase the reliability of the fuel sampling processes ship owners are required to carry out in order to comply with the international MARPOL Treaty, ANNEX VI.

Up until 2022, manufacturing took place at the Fuelsampler facility according to received purchase orders.

Attention to climate change has led to an increased market potential!

Today where environmental concerns can lead to numerous changes in legal and regulatory policies, Fuelsampler ApS recognized the need for a product that increases both measurement accuracy & reliability.

This – combined with a general increase in sales ambitions – has naturally led to considerations regarding product strategy and production setup.

Production implementation and ATEX certification

These considerations led Fuelsampler ApS to depart from their traditional bespoke solutions manufacturing model. Instead a standardized product line that covers the various customer segment requirements would be developed and a scalable production setup put in place. In addition future regulations necessitated that such a product line be ATEX-certified.

Building scalable production requires considerable effort, resources and manufacturing experience. For this reason, Fuelsampler ApS made the decision to focus their own organization on its core competencies and outsourcing their production and its implementation to SinoScan.

Ready for growth with an optimized, scalable production setup

In 2022, SinoScan was given the opportunity to assist Fuelsampler ApS with production implementation and subsequently to work as their OEM. Sinoscan optimized all parts of the supply chain and production processes – to ensure the quality standards of the production setup, and in order to fulfill requirements related to the ATEX certification process.

During our work with Fuelsampler ApS, we have:

- Delivered production-ready drawing and documentation .

- Analyzed and optimized the supplier base – giving preference to a local supply chain

- Established production lines at SinoScan’s facilities

- Established production and QA workflows and trained production staff

Additionally, SinoScan took on the role as technically proficient project manager during the coordinated work on acquiring ATEX certification. A work that – apart from the drafting technical documentation – required significant coordination between all parties involved.

Today, Fuelsampler, has a well-engineered, ATEX-certified product, an optimized supply chain and a scalable production setup, ready for a dynamic market.

In SinoScan we have met a partner, who could serve as product developer, product engineer and actual product manufacturer.

SinoScan's combination of development and manufacturing capabilities has given the entire project an enormous boost. Among other things, they helped secure ATEX-certification of our Fuelsampler at the Danish Institute for Techology. I have nothing but praise for our partnership with SinoScan, and warmly recommend them.

Marco Marine A/S

From special orders to mass production - The story of optimizing the FS 5051 Fuelsampler.

SinoScan collaborates with Marco Marine on production upgrades and ATEX certification.

Optimization of the Fuelsampler

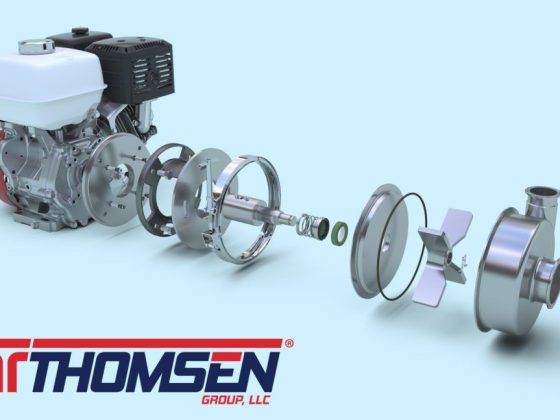

Marco Marine A/S develops and manufactures fuel samplers. Drawing on the owners’ solid experience and high technical expertise, Marco Marine A/S develops and manufactures automated, pneumatic samplers. These automatic samplers improve the reliability of fuel samples that ships are required to take in accordance with the international MARPOL Annex VI regulations.

Until 2022, Marco Marine A/S managed the manufacturing of samplers in-house, with production characterized by customized customer solutions.

From Vision to Full Production - The Story of the FS5051 Fuelsampler

With an increasing focus on fuel quality assurance in larger ships, Marco Marine A/S recognized the need to develop a product that could continuously take fuel samples during voyages. These samples were to be used for quality control and validation.

The product, which originally emerged as a solution to this problem, was developed internally by Marco Marine A/S and was subsequently verified as a reliable solution for continuous sampling.

Increased demand and stricter regulations led Marco Marine A/S to see an opportunity to optimize their product strategy.

Delivered services

Engineering

Manufacturing

Customized Services

Optimization of the Supplier Base

Workflows for Production and Quality Assurance

Training Employees in the Assembly Process

Lead Role in the ATEX Certification Process

Deliveries

The goal was clear for both Marco Marine A/S and the engineers at SinoScan: to create a product ready for larger-scale production and meet the high-quality standards required by ATEX certification.

Based on the successful prototype, a production process was developed that was both efficient and met ATEX certification requirements. This resulted in the creation of production drawings and materials.

SinoScan contributed to Marco Marine A/S’ fuelsampler project by delivering the following results:

- Production-ready drawings and documentation with increased detail.

- Analysis, simplification, and optimization of the supplier base with a focus on Danish suppliers.

- Establishment of a production line in SinoScan’s assembly department in Vejle.

- Development of workflows for production and quality assurance, as well as training employees in assembly.

- Lead role in achieving ATEX certification.

Outcome

From Prototype to a Stable Supplier Network.

Marco Marine A/S now has a finished product, a reliable supply chain, ATEX certification, and compliance with MARPOL regulations. This provides Marco Marine A/S with a solid platform to expand their business and help shipping companies worldwide ensure the quality of the fuel they use for their vessels.

Collaboration with Benefits

ATEX, DNV, MARPOL Annex VI – Quality is defined through many certifications, and that has been the goal from the beginning.

As part of the product strategy optimization, where Marco Marine A/S shifted their production to a lean-optimized process, the goal was also to have the product certified to the highest standards.

With ISO 9001:2015 certification in place, the foundation was established to have the FS 5051 Fuelsampler certified for use in explosive environments.

Preparation and Documentation

Building scalable production requires considerable effort, resources, and manufacturing experience.

Therefore, Marco Marine A/S made the decision to fully focus on their core competencies and outsource production.

During the development process, SinoScan has focused on establishing a solid and understandable foundation for production, ensuring that every delivery meets the high-quality standards required.

As part of this process, SinoScan has established assembly lines in Denmark, from which the production of the FS 5051 Fuelsampler can be scaled according to future demand.

“

In SinoScan, we have met a partner who could serve as a product developer, product engineer, and actual product manufacturer. SinoScan’s combination of development and production expertise has given a huge boost to the project – they have, among other things, been responsible for securing ATEX certification of our Fuelsampler through the Danish Technological Institute. I have nothing but praise for our partnership with SinoScan, and warmly recommend them.

Casper Staal

Direktør, Fuelsampler ApS og Teknisk Chef, Marco Marine A/S